Production of arched windows

Photo series from the production of copies of original windows for a building in the historic center of the city.

These are oak arched casement windows opening outwards and inwards on a brick casement with a decorative flap and simple windows opening inwards.

Oak planks ready for window production

Shortening material

Fosnia landscape cropping

Planing the edges of the wood

After this preparation of the slats, the slats will be cut into prisms, which will ultimately make up the windows. Next, we are processing these prisms...

Planing prisms

Prepared, planed and marked prisms

Preparation for the production of frame arches

Glued prisms to the arch of the window frame

Fixing the window arch

One piece window frame arch

Fries of window frames

Prisms of window frames ready for tenoning

Tapping the frame arch

Frame arches with studs

Folding the frame arch

Adjusting the depth of the rebate

Tapping prisms of the frames

Prisms for completing window frames

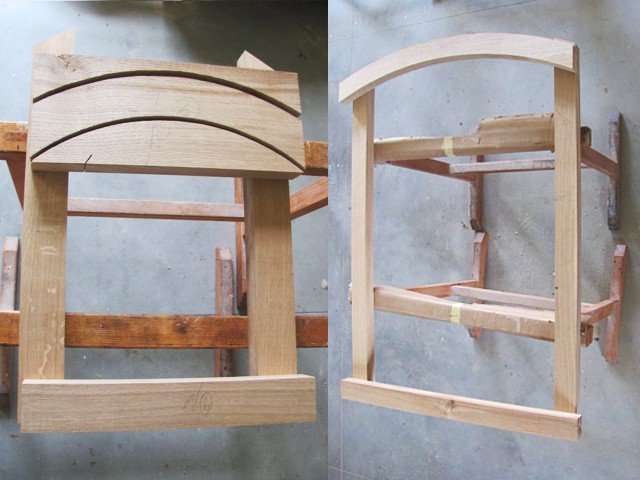

Harvested window frames

So we should have the frames ready, the preparation of the parts of the window sashes starts similarly to the parts of the frames. The cut, planed material must be measured, then the arches of the upper parts of the wings are cut out, and on all prisms, pins and rebates are prepared at the point of connection.

Arches of window sashes

Tapping and hollowed window sash prisms

Window sashes ready for gluing

Window sashes ready for gluing

The parts are first fitted dry to adjust the depth of the rebates. Then comes the gluing.

Harvested window sashes

Sash with frame

Sash with frame

Now most of the windows are finished. Furthermore, the windows will be equipped with drips, metal parts and other decorative elements.

Milled drip trays

Cut-out hole for window tab

Drilling a hole in the flapper for the wheelbase lock

Splits in flaps and holes for them

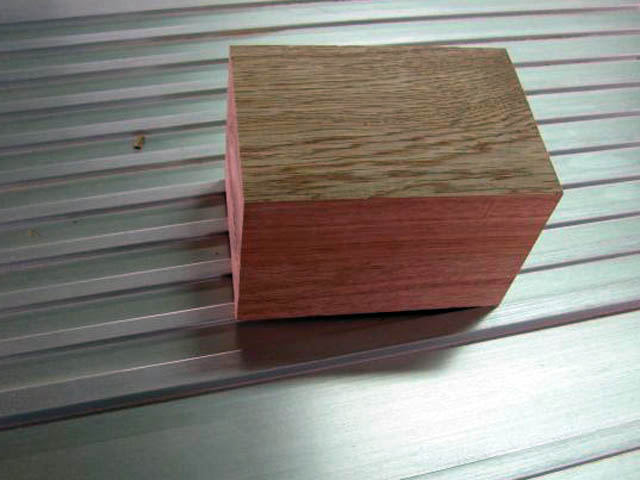

A part of the window will be a decorative flap. Two prisms were harvested for turning, which were then trimmed to the correct size.

Part ready for turning

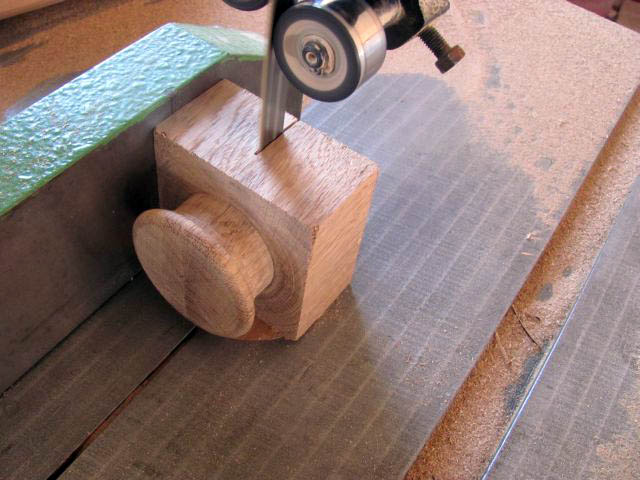

Turning of the base of the decorative flapper

Sockets clamped in a lathe, whole and separate

Turning of the head of a decorative flapper

Semi-finished decorative clapper heads

Having before carving

Semi-finished decorative clapper heads

Carved window shutter heads

Completing the decorative flapper

Cut-out hole for hinge hinge placement

Secure the hinge with pins

Riveted window curtains

Attached drip trays and decorative clapper

Decorative window capitals

Windows ready to fit glazing bars

Production of glazing beads

Almost finished window - interior view

Almost finished window - exterior view

Finished window before glazing

Finished window after final assembly

Finished window after final assembly